News

1、 Installation steps

1. Equipment cleaning and inspection

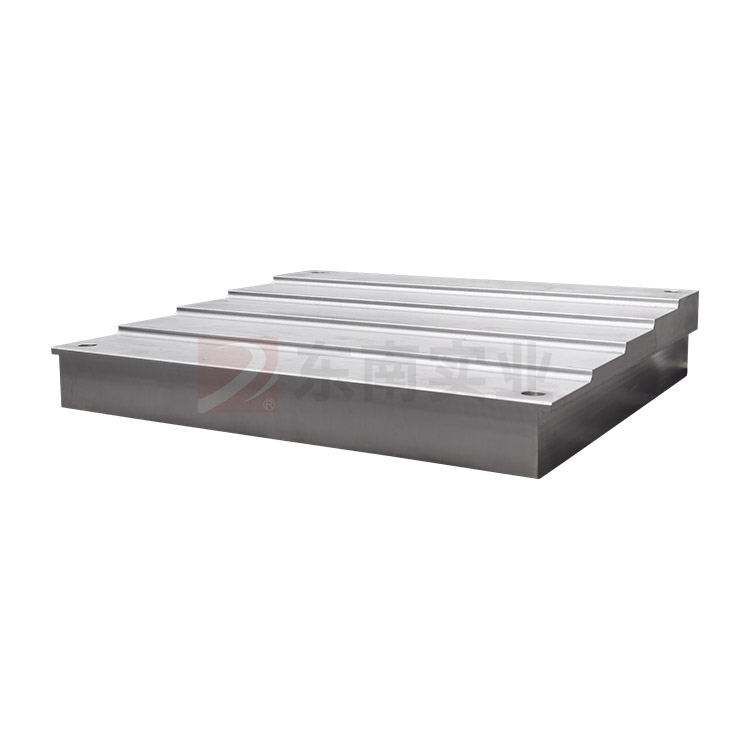

● Comprehensive cleaning: before installation, the contact surface of the ladder pad body, base and memorial archway shall be thoroughly cleaned to remove oil stains, iron filings and other impurities, so as to prevent poor contact or wear caused by foreign matters after installation.

● Key component inspection:

Check whether the steps of the step pad are flat and whether the height difference between adjacent steps is consistent (usually designed as the same difference).

Confirm whether the slag discharge groove is unobstructed to avoid residual processing residue affecting equipment operation.

Check if the base, pressure equalization pad, pressure gauge replacement device and other accessories are intact, ensuring no cracks or deformations.

2. Base installation and adjustment

● Positioning installation: install the base in the lower window of the two memorial archway, check the contact surface with a 0.05mm feeler gauge, ensure that there is no gap in more than 70% of the area, and allow a maximum gap of 0.1mm locally.

Horizontal adjustment: By adjusting the bolts or washers at the four corners of the base, the horizontal error of the base should be ≤ 0.1mm/m to prevent uneven force on the step pad due to installation tilt.

3. Installation of stair cushion body

● Layered assembly:

Install the pressure equalization pad, pressure gauge substitute device, upper pressure plate, and base pad in sequence (note that the positions of the three specifications of base pads cannot be placed incorrectly).

Install the bracket, track, support, and oil cylinder support to ensure that the tightening torque of the connecting bolts meets the design requirements (such as M56 bolts requiring the specified torque).

Alignment of slag discharge groove: Adjust the direction of the step pad to align the slag discharge groove with the slag discharge system of the rolling mill, facilitating the discharge of dust and residue.

4. Hydraulic system connection

Oil cylinder installation: Connect the oil cylinder to the support, ensure that there is no leakage in the hydraulic pipeline, and test whether the oil cylinder moves smoothly.

Sensor calibration: Install displacement sensors and eliminate installation deviations through calibration procedures to ensure measurement accuracy of ≤ 0.01mm/pulse cycle.

2、 Maintenance methods

1. Daily inspection

● Contact surface inspection: check the contact surface between the step pad and the base and memorial archway every day, and use a feeler gauge to confirm whether the clearance exceeds the standard (locally ≤ 0.1mm).

Cleaning of slag discharge tank: Remove dust and residue from the slag discharge tank to prevent blockage and affect the slag discharge effect.

Hydraulic system inspection: Check whether the oil cylinder leaks oil and whether the hydraulic pipeline is loose to ensure stable system pressure.

2. Regular maintenance

Bolt tightening: Check all connecting bolts (such as M56 bolts) weekly for looseness and tighten them to the specified value using a torque wrench.

Sensor calibration: Perform zero point calibration on displacement sensors every month to eliminate deviations caused by long-term operation.

Lubrication and maintenance: Apply high-temperature resistant grease to the sliding parts of the step pad (such as tracks and supports) to reduce wear.

3. Fault handling

Step pad flipping:

Reason: The curved surface design of the shaft contact surface leads to insufficient anti overturning torque, or the accumulation of oil sludge increases friction.

Solution: Optimize the design of the slag discharge tank and increase the frequency of cleaning; Apply lubricating grease to the corners of the pressure gauge box to reduce friction.

● Sensor damage:

Reason: The deformation of the base plate causes the sensor to be impacted, or environmental vibration leads to loose wiring.

Solution: Replace high-strength sensors and install shock absorbers; Regularly check if the wiring is secure.

● Bottom plate deformation:

Reason: Alternating stress during rolling, or HAGC adjustment causing inconsistent elevation of the north and south sides of the bottom plate.

Processing: Perform stress relief treatment on the bottom plate (such as vibration aging), or optimize the HAGC adjustment strategy.

4. Replacement and repair

● Step pad replacement:

When disassembling, use a special tool (such as M56 × 520 hex bolt) to pull up the bottom plate to avoid deformation caused by direct tapping.

When installing a new step pad, ensure that the bolt holes are aligned and use locating pins to assist in positioning.

Surface repair:

Laser cladding repair is performed on worn step planes to restore surface hardness (such as HRC55-60).

Apply a corrosion-resistant coating (such as Cr Ni alloy) to the corroded bottom surface to extend its service life.

3、 Optimization suggestions

1. Design improvement:

Change the contact surface of the stepped pad shaft to a rectangular design to enhance its anti overturning ability (the impact on installation and self leveling needs to be evaluated).

Install high-pressure water circuits (pressure ≥ 0.9MPa) on both sides of the lifting track to automatically remove the accumulation of iron oxide scale.

2. Standardized homework:

Develop standardized procedures for the installation and maintenance of stair mats, specifying inspection items and frequency.

Train operators to improve fault handling efficiency (such as reducing roller replacement time to within 0.5 hours).

3. Status monitoring:

Install vibration sensors to monitor the real-time operation status of the step pad and provide early warning of potential faults.

Establish maintenance files to record each inspection and repair data, providing a basis for optimizing maintenance strategies.