News

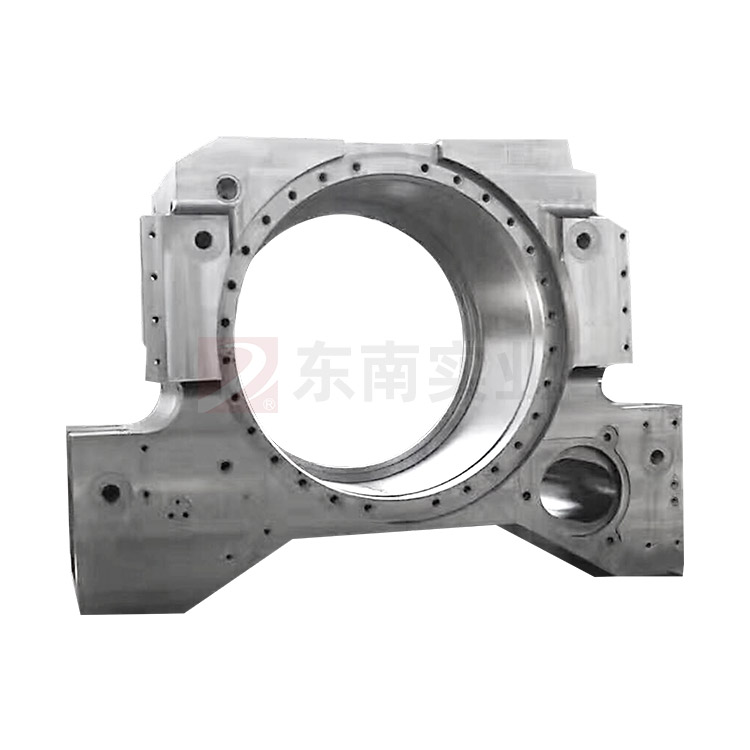

Bearing seat is a key component used to support and fix bearings in mechanical equipment. Its core function is to provide stable and reliable support for rotating shafts or transmission components, ensuring smooth operation of the equipment. The following are the specific functions and key details of the bearing seat:

1、 Core functions

1. Supporting rotating components

The bearing seat carries the weight of transmission components such as rotating shafts, gears, pulleys, etc. through built-in bearings (such as rolling bearings or sliding bearings), and transmits the radial force (such as gear meshing force) and axial force (such as threaded transmission thrust) generated by motion.

Example: In a car engine, the bearing seat supports the crankshaft to ensure that it does not shift due to centrifugal force or vibration during high-speed rotation.

2. Fixed bearing position

The bearing seat precisely fixes the bearing in the design position of the equipment, preventing axial displacement (movement along the axis direction) and radial jumping (offset perpendicular to the axis direction), ensuring transmission accuracy.

Key design: Accurate alignment between bearings and bearing seats is achieved through positioning pins, bolts, or keyways, with errors typically controlled within 0.01mm.

3. Transmitting loads and dispersing stresses

The bearing seat transfers the load borne by the bearing (such as equipment weight and working load) to the machine base or frame, and disperses the stress through its own structure (such as reinforcing ribs and flanges) to avoid local deformation or fracture.

Material selection: commonly used gray cast iron (HT200-300), ductile iron (QT400-15), or cast steel (ZG230-450) to balance strength, stiffness, and shock absorption.

2、 Additional features

1. Lubrication and Sealing

Lubrication: The bearing seat is designed with oil grooves, oil holes or oil cups, which can be filled with lubricating grease or oil to reduce bearing friction and wear, and extend service life.

Sealing: Equipped with dust covers, sealing rings, or labyrinth sealing structures to prevent dust, moisture, or corrosive media from entering the interior of the bearing, avoiding lubrication failure or corrosion.

Example: The bearing seat of the wind turbine gearbox adopts a dual sealing design to ensure reliable operation in dusty environments.

2. Heat dissipation and temperature control

The bearing seat is designed with heat dissipation fins, circulating cooling water channels, or forced ventilation to help dissipate heat from the bearing and prevent lubricating oil deterioration or bearing material softening caused by high temperatures.

Data: The surface temperature of high-speed motor bearing seats usually needs to be controlled below 60 ℃ to avoid lubrication failure.

3. Installation and maintenance convenience

The bearing seat is designed as a detachable structure (such as a split type bearing seat), which facilitates bearing replacement, cleaning, or maintenance and reduces equipment downtime.

Standardization: Some bearing seats adopt international standards (such as ISO, DIN) or industry specifications (such as API, GB) to improve interchangeability and universality.

3、 Application scenarios

1. Industrial Machinery

Machine tool: supports the spindle to ensure machining accuracy (such as the coaxiality of the spindle bearing seat of a CNC milling machine ≤ 0.005mm).

Reducer: Fixed gear shaft bearings, transmitting high torque (such as the bearing seat of a mining reducer with a bearing capacity of up to 1000kN · m).

Compressor: Supports the crankshaft or piston rod and withstands reciprocating motion impacts (such as the bearing seat of a reciprocating compressor, which needs to have a lifespan of ≥ 20000 hours).

2. Automotive field

Engine: Supports the crankshaft and camshaft, and can withstand high temperature and high pressure (such as the working temperature of the diesel engine bearing seat reaching 150 ℃).

Transmission: Fixed gear shaft bearings to achieve multi-stage transmission (such as automatic transmission bearing seats that need to withstand shifting impact loads).

Wheel: The wheel hub bearing seat connects the wheel to the suspension system, transmitting driving and braking forces (such as heavy-duty truck wheel hub bearing seat with a load-bearing capacity of ≥ 50kN).

3. Energy and Heavy Industries

Wind power equipment: supports the main shaft and gearbox input shaft, and can withstand extreme loads (such as a radial force of 3000kN on the bearing seat of a 5MW wind turbine).

Mining machinery: Fixed crusher spindle bearings, resistant to impact and wear (such as jaw crusher bearing seat using high manganese steel lining plate).

Ship propulsion: Support the propeller shaft to prevent seawater corrosion (such as using stainless steel or anti-corrosion coating for ship bearing seats).

4、 Structure type

1. Integral bearing seat

Structure: The bearing and seat are integrally formed, with good rigidity but inconvenient maintenance.

Application: Low speed, light load scenarios (such as small motors, fans).

2. Split type bearing seat

Structure: Composed of an upper cover and a base, connected by bolts for easy installation and disassembly.

Application: High speed and heavy-duty scenarios (such as rolling mills and crushers).

3. With flange bearing seat

Structure: The seat is equipped with a flange, which can be directly bolted onto the surface of the equipment.

Application: Space constrained scenarios (such as conveyor rollers, packaging machinery).

4. Suspended bearing seat

Structure: Fixed above the equipment by hanging bolts, saving space.

Application: Lightweight transmission systems (such as textile machinery, food processing equipment).