Products

Products

The technical indicators of the composite skateboard we have developed have reached the performance of the same imported product, and its service life is comparable to that of imported composite skateboards. It is 4-5 times larger than nitride steel sliding plates and fully meets the conditions to replace imported composite sliding plates, fundamentally solving the supply of spare parts for medium thick plates and hot rolling mills. Breaking the long-standing monopoly of Europe on the Chinese metallurgical industry market, innovation has filled the domestic gap. Due to the long service life of composite skateboards, while ensuring the quality of steel rolling, the cycle of replacing lining plates in the rolling mill is extended, downtime is reduced, production efficiency is improved, spare parts consumption is reduced, maintenance costs are saved, and significant economic and social benefits are achieved.

Skateboard features and craftsmanship

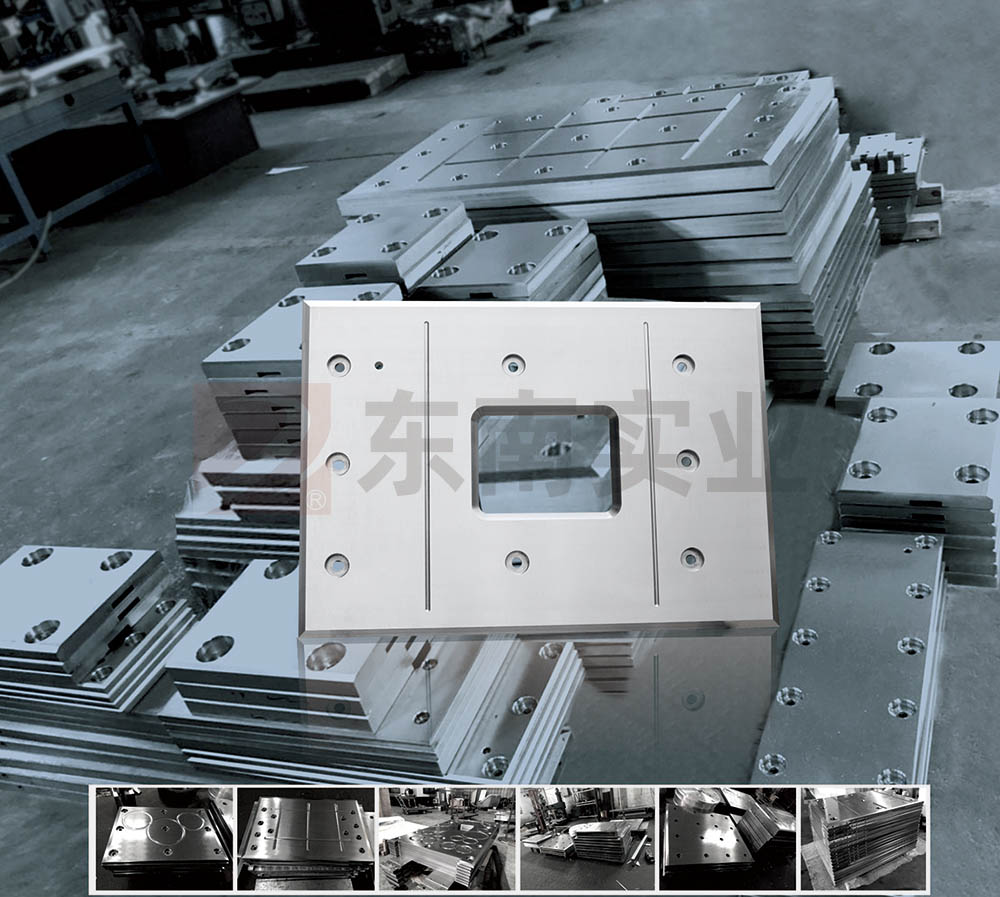

The rolling mill composite sliding plate is made of composite materials, which are composed of two different materials. One is a high wear-resistant stainless alloy material with a wear-resistant layer thickness greater than 25% of the total thickness (6mm-10mm), which is treated to achieve high hardness as the friction surface. The remaining material is a low-carbon and low hardness material, which utilizes its good toughness to achieve impact resistance and protect the frame from wear. The base layer and wear-resistant layer of the skateboard are composite by rolling, explosion, fusion welding, and other methods.

The skateboard formed by fusion welding is metallurgically bonded, with a bonding rate of 100%, ensuring that the substrate layer and wear-resistant layer will not deform, crack, or peel off. This metal material forms continuous metallurgical bonding in the solid state, without fundamentally changing the chemical composition, structure, and corrosion resistance of the original component materials. The bonding strength is superior to products obtained by other solid bonding methods. The wear-resistant layer of the skateboard has a thickness greater than 25% of the total thickness, ensuring the product's wear resistance, deformation ability, and flatness. Skateboards are compounded through special processing techniques, possessing the corrosion resistance, wear resistance, and diamagnetism of stainless steel; It also has good weldability, formability, stretchability, and thermal conductivity of carbon steel.. In the chemical composition of the wear-resistant alloy layer of the skateboard, the chromium content is high, and the volume fraction of Cr7C3 carbides in its metallographic structure reaches more than 50%. The macroscopic hardness is HRC50-55, and the hardness of chromium carbide is HV1400-1800. Due to the perpendicular distribution of carbides in the direction of wear, even compared with casting alloys of the same composition and hardness, the wear resistance is greatly improved. The base layer of the skateboard is made of tough materials such as low carbon steel, low alloy, or stainless steel. Reflecting the superiority of bimetallic materials, the wear-resistant layer resists wear, and the base layer bears loads, thus having good wear resistance and impact resistance.

The technical indicators of the composite skateboard we have developed have reached the performance of the same imported product, and its service life is comparable to that of imported composite skateboards. It is 4-5 times larger than nitride steel sliding plates and fully meets the conditions to replace imported composite sliding plates, fundamentally solving the supply of spare parts for medium thick plates and hot rolling mills. Breaking the long-standing monopoly of Europe on the Chinese metallurgical industry market, innovation has filled the domestic gap. Due to the long service life of composite skateboards, while ensuring the quality of steel rolling, the cycle of replacing lining plates in the rolling mill is extended, downtime is reduced, production efficiency is improved, spare parts consumption is reduced, maintenance costs are saved, and significant economic and social benefits are achieved.

Basic parameters of wear-resistant composite skateboard:

Wear resistant layer thickness mm 5-15mm (accounting for more than 25% of the total thickness)

Base thickness mm 15-50mm (accounting for less than 75% of the total thickness)

Base course hardness HB 140-180 (protect memorial archway and bearing pedestal)

Wear resistant layer hardness HRC 50-55 Surface roughness: 0.8-3.2