Products

Products

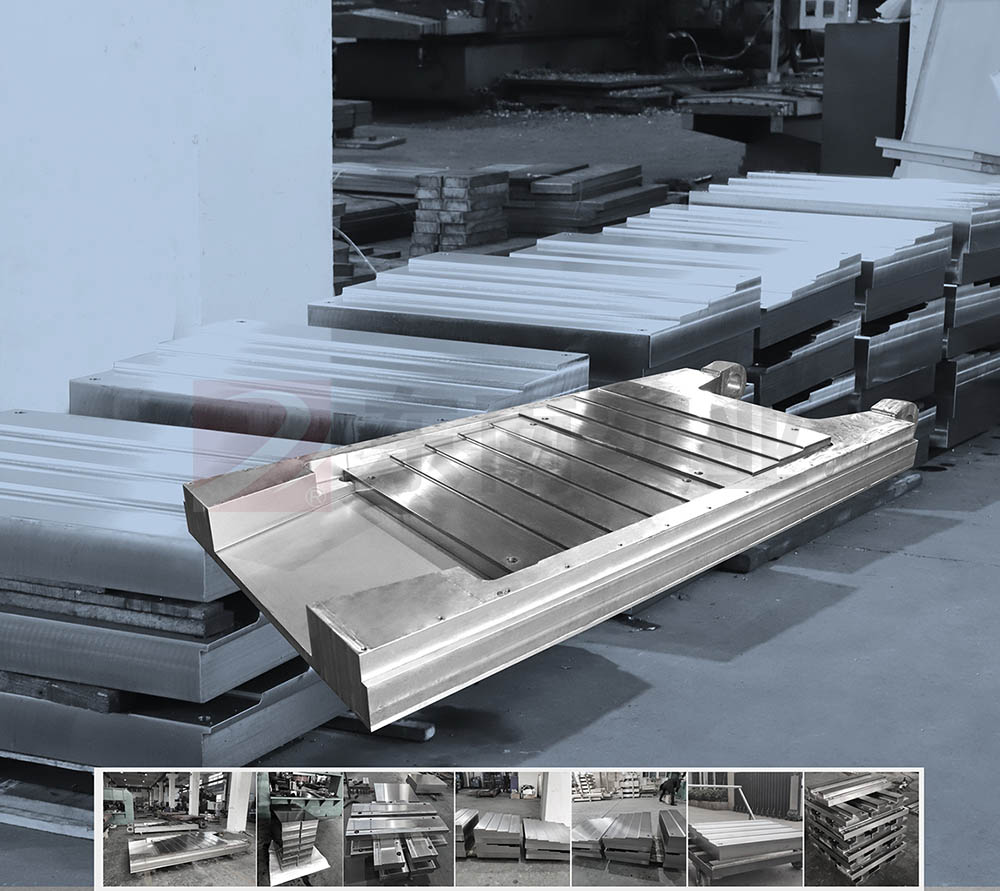

Characteristics and Description of Ladder Mat

In order to ensure the efficient, stable, and reliable operation of the rolling mill equipment, improve the operating rate and yield of the rolling mill, and maximize the benefits. The optimization and transformation of the rolling mill step pad adjustment device ensures the normal operation of the rolling mill, reduces the occurrence of faults, and lowers the consumption and cost of spare parts. The material, heat treatment process, and surface treatment of the rolling mill step pad have been modified. DNTZ-80 high-quality high-strength low-carbon alloy steel forgings are used as the base material, and corrosion-resistant and wear-resistant alloy material fusion welding process is used on the hard surface layer of the step pad. The thickness of the fusion welding layer of the product is 6-8mm, and the hardness reaches HRC50-55. The composite structure step pad made of high hardness and corrosion-resistant materials not only ensures good overall mechanical properties, but also achieves high hardness, wear resistance, and corrosion resistance on the surface. It has a service life more than three times that of the original step pad, with good cost-effectiveness and significant economic and social benefits.

Characteristics and Description of Ladder Mat

In order to ensure the efficient, stable, and reliable operation of the rolling mill equipment, improve the operating rate and yield of the rolling mill, and maximize the benefits. The optimization and transformation of the rolling mill step pad adjustment device ensures the normal operation of the rolling mill, reduces the occurrence of faults, and lowers the consumption and cost of spare parts. The material, heat treatment process, and surface treatment of the rolling mill step pad have been modified. DNTZ-80 high-quality high-strength low-carbon alloy steel forgings are used as the base material, and corrosion-resistant and wear-resistant alloy material fusion welding process is used on the hard surface layer of the step pad. The thickness of the fusion welding layer of the product is 6-8mm, and the hardness reaches HRC50-55. The composite structure step pad made of high hardness and corrosion-resistant materials not only ensures good overall mechanical properties, but also achieves high hardness, wear resistance, and corrosion resistance on the surface. It has a service life more than three times that of the original step pad, with good cost-effectiveness and significant economic and social benefits.